In the 1990s, when silicon cells were twice as thick, efficiencies were much lower than today and lifetimes were shorter, it may well have cost more energy to make a cell than it could generate in a lifetime. In the meantime, the technology has progressed significantly, and the energy payback time, defined as the recovery time required for generating the energy spent for manufacturing of the respective technical energy systems, of a modern photovoltaic module is

Thursday, September 30, 2010

Wednesday, September 29, 2010

Equivalent circuit of a solar cell

The equivalent circuit of a solar cell

/wiki/File:Photovoltaic_cell.svg">

The schematic symbol of a solar cell

To understand the electronic behavior of a solar cell, it is useful to create a model which is electrically equivalent, and is based on discrete electrical components whose behavior is well known. An ideal solar cell may be modelled by a

Tuesday, September 28, 2010

Thin films

The various thin-film technologies currently being developed reduce the amount (or mass) of light absorbing material required in creating a solar cell.

This can lead to reduced processing costs from that of bulk materials (in the case of silicon thin films) but also tends to reduce energy conversion efficiency (an average 7 to 10% efficiency), although many multi-layer thin films have efficiencies above those of bulk silicon wafers.

They have become popular compared to wafer silicon due to lower costs and advantages including flexibility, lighter weights, and ease of integration.

This can lead to reduced processing costs from that of bulk materials (in the case of silicon thin films) but also tends to reduce energy conversion efficiency (an average 7 to 10% efficiency), although many multi-layer thin films have efficiencies above those of bulk silicon wafers.

They have become popular compared to wafer silicon due to lower costs and advantages including flexibility, lighter weights, and ease of integration.

Monday, September 27, 2010

Cadmium telluride solar cell

A cadmium telluride solar cell is a solar cell based on cadmium telluride, an efficient light-absorbing material for thin-film cells. Compared to other thin-film materials, CdTe is easier to deposit and more suitable for large-scale production.

There has been much discussion of the toxicity of CdTe-based solar cells. The perception of the toxicity of CdTe is based on the toxicity of elemental cadmium, a heavy metal that is a

There has been much discussion of the toxicity of CdTe-based solar cells. The perception of the toxicity of CdTe is based on the toxicity of elemental cadmium, a heavy metal that is a

Quantum efficiency of Solar Cells

As described above, when a photon is absorbed by a solar cell it can produce a pair of free charge carriers, i.e. an electron-hole pair. One of the carriers (the minority carrier) may then be able to reach the p-n junction and contribute to the current produced by the solar cell; such a carrier is said to be collected. Alternatively, the carrier may give up its energy and once again become bound to an atom within the solar cell without

Sunday, September 26, 2010

Light-absorbing materials

All solar cells require a light absorbing material contained within the cell structure to absorb photons and generate electrons via the photovoltaic effect. The materials used in solar cells tend to have the property of preferentially absorbing the wavelengths of solar light that reach the Earth surface. However, some solar cells are optimized for light absorption beyond Earth's atmosphere as well. Light absorbing materials can often be used in multiple physical configurations to take advantage of different light absorption and charge separation mechanisms.

Photovoltaic panels are normally made of either silicon or thin-film cells:

Many currently available solar cells are configured as

Photovoltaic panels are normally made of either silicon or thin-film cells:

Many currently available solar cells are configured as

The p-n junction of Solar Cell

The most commonly known solar cell is configured as a large-area p-n junction made from silicon. As a simplification, one can imagine bringing a layer of n-type silicon into direct contact with a layer of p-type silicon. In practice, p-n junctions of silicon solar cells are not made in this way, but rather by diffusing an n-type dopant into one side of a p-type wafer (or vice versa).

If a piece of p-type silicon is placed in intimate contact with a piece of n-type silicon, then a diffusion of electrons occurs from the

If a piece of p-type silicon is placed in intimate contact with a piece of n-type silicon, then a diffusion of electrons occurs from the

Saturday, September 25, 2010

Thin-film solar cells

In 2002, the highest reported efficiency for thin film solar cells based on CdTe is 18%, which was achieved by research at Sheffield Hallam University, although this has not been confirmed by an external test laboratory.

The US national renewable energy research facility NREL achieved an efficiency of 19.9% for the solar cells based on copper indium gallium selenide thin films, also known as CIGS .

NREL has since developed a robot that builds and analyzes the efficiency of thin-film solar cells with the goal of increasing the efficiency by testing the cells in different situations.

These CIGS films have been grown by

The US national renewable energy research facility NREL achieved an efficiency of 19.9% for the solar cells based on copper indium gallium selenide thin films, also known as CIGS .

NREL has since developed a robot that builds and analyzes the efficiency of thin-film solar cells with the goal of increasing the efficiency by testing the cells in different situations.

These CIGS films have been grown by

Friday, September 24, 2010

Crystalline silicon

Basic structure of a silicon based solar cell and its working mechanism.

By far, the most prevalent bulk material for solar cells is crystalline silicon (abbreviated as a group as c-Si), also known as "solar grade silicon". Bulk silicon is separated into multiple categories according to crystallinity and crystal size in the resulting ingot, ribbon, or wafer.

- monocrystalline silicon (c-Si): often made using the Czochralski process. Single-crystal wafer cells tend to be expensive, and because they are cut from cylindrical ingots, do not

Thursday, September 23, 2010

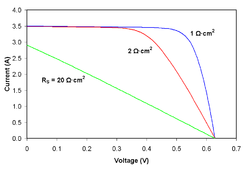

Series resistance

Effect of series resistance on the current-voltage characteristics of a solar cell

As series resistance increases, the voltage drop between the junction voltage and the terminal voltage becomes greater for the same flow of current. The result is that the current-controlled portion of the I-V curve begins to sag toward the origin, producing a significant decrease in the terminal voltage V and a slight reduction in ISC, the short-circuit current. Very high values of RS will also

Wednesday, September 22, 2010

Cell Temperature | Solar Cell

Effect of temperature on the current-voltage characteristics of a solar cell

Temperature affects the characteristic equation in two ways: directly, via T in the exponential term, and indirectly via its effect on I0 (strictly speaking, temperature affects all of the terms, but these two far more significantly than the others). While increasing T reduces the magnitude of the exponent in the characteristic equation, the value of I0 increases exponentially with T. The net effect is to

Tuesday, September 21, 2010

High-efficiency cells

High-efficiency solar cells are a class of solar cell that can generate more electricity per incident solar power unit (watt/watt). Much of the industry is focused on the most cost efficient technologies in terms of cost per generated power.

The two main strategies to bring down the cost of photovoltaic electricity are increasing the efficiency of the cells and decreasing their cost per unit area. However, increasing the efficiency of a solar cell without

The two main strategies to bring down the cost of photovoltaic electricity are increasing the efficiency of the cells and decreasing their cost per unit area. However, increasing the efficiency of a solar cell without

Monday, September 20, 2010

Light-absorbing dyes (DSSC)

Typically a ruthenium metalorganic dye (Ru-centered) is used as a monolayer of light-absorbing material. The dye-sensitized solar cell depends on a mesoporous layer of nanoparticulate titanium dioxide to greatly amplify the surface area (200–300 m2/g TiO2, as compared to approximately 10 m2/g of flat single crystal). The photogenerated electrons from the light absorbing dye are passed on to the n-type TiO2, and the holes are passed to an electrolyte on the

Sunday, September 19, 2010

Concentrating photovoltaics (CPV)

Concentrating photovoltaic systems use a large area of lenses or mirrors to focus sunlight on a small area of photovoltaic cells.High concentration means a hundred or more times direct sunlight is focused when compared with crystalline silicon panels. Most commercial producers are developing systems that concentrate between 400 and 1000 suns.

All concentration systems need a one axis or more often two axis tracking system for high precision, since

All concentration systems need a one axis or more often two axis tracking system for high precision, since

Saturday, September 18, 2010

Metamorphic multijunction solar cell

The National Renewable Energy Laboratory won one of R&D Magazine's R&D 100 Awards for its Metamorphic Multijunction Solar Cell, an ultra-light and flexible cell that converts solar energy with record efficiency.

The ultra-light, highly efficient solar cell was developed at NREL and is being commercialized by Emcore Corp.of Albuquerque, N.M., in partnership with the Air Force Research Laboratories Space Vehicles Directorate at

The ultra-light, highly efficient solar cell was developed at NREL and is being commercialized by Emcore Corp.of Albuquerque, N.M., in partnership with the Air Force Research Laboratories Space Vehicles Directorate at

Friday, September 17, 2010

Silicon processing

One way of reducing the cost is to develop cheaper methods of obtaining silicon that is sufficiently pure. Silicon is a very common element, but is normally bound in silica, or silica sand. Processing silica (SiO2) to produce silicon is a very high energy process - at current efficiencies, it takes one to two years for a conventional solar cell to generate as much energy as was used to make the silicon it contains. More energy efficient methods of synthesis are not only beneficial to the solar industry, but also to

Thursday, September 16, 2010

Nanoparticle processing

Experimental non-silicon solar panels can be made of quantum heterostructures, e.g. carbon nanotubes or quantum dots, embedded in conductive polymers or mesoporous metal oxides. In addition, thin films of many of these materials on conventional silicon solar cells can increase the optical coupling efficiency into the silicon cell, thus boosting the overall efficiency.

By varying the size of the quantum dots, the cells can be

By varying the size of the quantum dots, the cells can be

Wednesday, September 15, 2010

Silicon solar cell device manufacture

Solar-powered scientific calculator

Because solar cells are semiconductor devices, they share many of the same processing and manufacturing techniques as other semiconductor devices such as computer and memory chips. However, the stringent requirements for cleanliness and quality control of semiconductor fabrication are a little more relaxed for solar cells. Most large-scale commercial solar cell factories today make screen printed poly-crystalline silicon solar cells. Single crystalline wafers which are used in the semiconductor industry can be made into excellent high efficiency solar cells, but

Tuesday, September 14, 2010

Transparent conductors

Many new solar cells use transparent thin films that are also conductors of electrical charge. The dominant conductive thin films used in research now are transparent conductive oxides (abbreviated "TCO"), and include fluorine-doped tin oxide (SnO2:F, or "FTO"), doped zinc oxide (e.g.: ZnO:Al), and indium tin oxide (abbreviated "ITO").

These conductive films are also used in the

These conductive films are also used in the

Monday, September 13, 2010

Silicon wafer-based solar cells

Despite the numerous attempts at making better solar cells by using new and exotic materials, the reality is that the photovoltaics market is still dominated by silicon wafer-based solar cells (first-generation solar cells). This means that most solar cell manufacturers are currently equipped to produce this type of solar cells. Consequently, a large body of research is being done all over the world to manufacture silicon wafer-based solar cells at lower cost and to

Sunday, September 12, 2010

Metamaterials

Metamaterials are heterogeneous materials employing the juxtaposition of many microscopic elements, giving rise to properties not seen in ordinary solids.

Using these, it may become possible to fashion solar cells that are excellent absorbers over a narrow range of wavelengths. High absorption in the microwave regime has been demonstrated,but

Using these, it may become possible to fashion solar cells that are excellent absorbers over a narrow range of wavelengths. High absorption in the microwave regime has been demonstrated,but

Saturday, September 11, 2010

Infrared solar cells

Researchers at Idaho National Laboratory, along with partners at Microcontinuum Inc. in Cambridge, MA and Patrick Pinhero of the University of Missouri, have devised an inexpensive way to produce plastic sheets containing billions of nanoantennas that collect heat energy generated by the sun and other sources, which garnered two 2007 Nano50 awards.

The technology is the first step toward a

The technology is the first step toward a

Friday, September 10, 2010

Silicon thin films

Silicon thin-film cells are mainly deposited by chemical vapor deposition (typically plasma-enhanced (PE-CVD)) from silane gas and hydrogen gas. Depending on the deposition parameters, this can yield:

- Amorphous silicon (a-Si or a-Si:H)

- Protocrystalline silicon or

- Nanocrystalline silicon (nc-Si or nc-Si:H), also called microcrystalline silicon.

Thursday, September 9, 2010

Polymer processing

The invention of conductive polymers (for which Alan Heeger, Alan G. MacDiarmid and Hideki Shirakawa were awarded a Nobel prize) may lead to the development of much cheaper cells that are based on inexpensive plastics. However, organic solar cells generally suffer from degradation upon exposure to UV light, and hence have lifetimes which are far too short to

Wednesday, September 8, 2010

3D solar cells

3D solar cells

Three-dimensional solar cells that capture nearly all of the light that strikes them and could boost the efficiency of photovoltaic systems while reducing their size, weight and mechanical complexity.The new 3D solar cells capture photons from sunlight using an array of

Tuesday, September 7, 2010

Thin-film processing

Thin-film photovoltaic cells can use less than 1% of the expensive raw material (silicon or other light absorbers) compared to wafer-based solar cells, leading to a significant price drop per Watt peak capacity. There are many research groups around the world actively researching different thin-film approaches and/or materials. However, it remains to be seen if these solutions can achieve a similar market penetration as

Monday, September 6, 2010

Photovoltaic Thermal Hybrid

Photovoltaic thermal hybrid

Systems which combine photovoltaic with thermal solar, the advantage of such a system is that the thermal solar part carries heat away and cools the photovoltaic cells, keeping temperature down lowers the resistance andSunday, September 5, 2010

Plasmonic solar cell

Plasmonic Solar Cells (PSC) are known as photovoltaic devices. They have great potential in driving the cost of solar power down. In order for the solar cell (SC) technology to be a viable energy source to compete with fossil fuels, the price needs to be reduced 2-5x. Approximately 90% of the market for solar cells use silicon wafers. These wafers are typically around 200-300μm and

Organic polymer solar cells

Organic solar cells and polymer solar cells are built from thin films (typically 100 nm) of organic semiconductors such as polymers and small-molecule compounds like polyphenylene vinylene, copper phthalocyanine (a blue or green organic pigment) and carbon fullerenes and fullerene derivatives such as

Saturday, September 4, 2010

Solar Tracker

A solar tracker is a generic term used to describe devices that orient various payloads toward the sun. Payloads can be photovoltaic panels, reflectors, lenses or other optical devices.

In standard photovoltaic (PV) applications trackers are used to minimize the angle of incidence between the incoming light and a photovoltaic panel. This increases the amount of energy produced from a

In standard photovoltaic (PV) applications trackers are used to minimize the angle of incidence between the incoming light and a photovoltaic panel. This increases the amount of energy produced from a

UV solar cells

UV solar cells

Japan's National Institute of Advanced Industrial Science and Technology (AIST) has succeeded in developing a transparent solar cell that uses ultraviolet (UV) light to generate electricity but allows visible light to pass through it.Most conventional solar cells use visible and infrared light to

Cost of Solar Cells

Solar Cell Costs

Cost is established in cost-per-watt and in cost-per-watt in 24 hours for infrared capable photovoltaic cells. Manufacturing costs are also calculated including the energy required for manufacturing of the cells and modules in a kWh basis. These figures are added to the end price for solar investors and the energy payback is calculated from the point of power plant initialization or connection to the grid. another method of calculating the payback is to use the feed in tariff mechanism in place forPhotogeneration of charge carriers

When a photon hits a piece of silicon, one of three things can happen:

- the photon can pass straight through the silicon — this (generally) happens for lower energy photons,

- the photon can reflect off the surface,

- the photon can be absorbed by the silicon, if the photon energy is higher than the silicon band gap value. This generates an electron-hole pair and sometimes heat, depending on the band structure.

Solar Roof

Building-integrated photovoltaics (BIPV) are photovoltaic materials that are used to replace conventional building materials in parts of the building envelope such as the roof, skylights, or facades.

They are increasingly being incorporated into the construction of new buildings as a principal or ancillary source of electrical power, although existing buildings may be retrofitted with

They are increasingly being incorporated into the construction of new buildings as a principal or ancillary source of electrical power, although existing buildings may be retrofitted with

Friday, September 3, 2010

How to Solar Cells Working

Simple explanation How to Solar Cells Working

- Photons in sunlight hit the solar panel and are absorbed by semiconducting materials, such as silicon.

- Electrons (negatively charged) are knocked loose from their atoms, allowing them to flow through the material to produce electricity. Due to the special composition of solar cells, the electrons are only allowed to move in a single direction.

- An array of solar cells converts

Solar Cells Applications and Implementations

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from the elements (rain, hail, etc.).

Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in

Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in

Solar power

Solar power is the generation of electricity from sunlight. This can be direct as with photovoltaics (PV), or indirect as with concentrating solar power (CSP), where the sun's energy is focused to boil water which is then used to provide power.

Solar power provided 0.02% of the total world energy consumption in 2008. The largest solar power plants, like the 354 MW SEGS, are concentrating solar thermal plants, but recently multi-megawatt photovoltaic plants have been built. Completed in 2008, the 46 MW Moura photovoltaic power station in Portugal and the 40 MW Waldpolenz Solar Park in Germany appear to be characteristic of the trend toward larger photovoltaic power stations. Larger ones are proposed, such as

Solar power provided 0.02% of the total world energy consumption in 2008. The largest solar power plants, like the 354 MW SEGS, are concentrating solar thermal plants, but recently multi-megawatt photovoltaic plants have been built. Completed in 2008, the 46 MW Moura photovoltaic power station in Portugal and the 40 MW Waldpolenz Solar Park in Germany appear to be characteristic of the trend toward larger photovoltaic power stations. Larger ones are proposed, such as

Solar Cells History

The term "photovoltaic" comes from the Greek φῶς (phōs) meaning "light", and "voltaic", meaning electric, from the name of the Italian physicist Volta, after whom a unit of electro-motive force, the volt, is named. The term "photo-voltaic" has been in use in English since 1849.

The photovoltaic effect was first recognized in 1839 by French physicist A. E. Becquerel. However, it was not until 1883 that the first solar cell was built, by

The photovoltaic effect was first recognized in 1839 by French physicist A. E. Becquerel. However, it was not until 1883 that the first solar cell was built, by

Thursday, September 2, 2010

Solar Cell

What is solar Cell ? A solar cell is a device that converts the energy of sunlight directly into electricity by the photovoltaic effect. Sometimes the term solar cell is reserved for devices intended specifically to capture energy from sunlight such as solar panels and solar cells, while the term photovoltaic cell is used when the light source is unspecified.

Assemblies of cells are used to make

Assemblies of cells are used to make

Subscribe to:

Posts (Atom)