The various thin-film technologies currently being developed reduce the amount (or mass) of light absorbing material required in creating a solar cell.

This can lead to reduced processing costs from that of bulk materials (in the case of silicon thin films) but also tends to reduce energy conversion efficiency (an average 7 to 10% efficiency), although many multi-layer thin films have efficiencies above those of bulk silicon wafers.

They have become popular compared to wafer silicon due to lower costs and advantages including flexibility, lighter weights, and ease of integration.

Showing posts with label solar cells. Show all posts

Showing posts with label solar cells. Show all posts

Tuesday, September 28, 2010

Monday, September 27, 2010

Cadmium telluride solar cell

A cadmium telluride solar cell is a solar cell based on cadmium telluride, an efficient light-absorbing material for thin-film cells. Compared to other thin-film materials, CdTe is easier to deposit and more suitable for large-scale production.

There has been much discussion of the toxicity of CdTe-based solar cells. The perception of the toxicity of CdTe is based on the toxicity of elemental cadmium, a heavy metal that is a

There has been much discussion of the toxicity of CdTe-based solar cells. The perception of the toxicity of CdTe is based on the toxicity of elemental cadmium, a heavy metal that is a

Quantum efficiency of Solar Cells

As described above, when a photon is absorbed by a solar cell it can produce a pair of free charge carriers, i.e. an electron-hole pair. One of the carriers (the minority carrier) may then be able to reach the p-n junction and contribute to the current produced by the solar cell; such a carrier is said to be collected. Alternatively, the carrier may give up its energy and once again become bound to an atom within the solar cell without

Sunday, September 26, 2010

Light-absorbing materials

All solar cells require a light absorbing material contained within the cell structure to absorb photons and generate electrons via the photovoltaic effect. The materials used in solar cells tend to have the property of preferentially absorbing the wavelengths of solar light that reach the Earth surface. However, some solar cells are optimized for light absorption beyond Earth's atmosphere as well. Light absorbing materials can often be used in multiple physical configurations to take advantage of different light absorption and charge separation mechanisms.

Photovoltaic panels are normally made of either silicon or thin-film cells:

Many currently available solar cells are configured as

Photovoltaic panels are normally made of either silicon or thin-film cells:

Many currently available solar cells are configured as

The p-n junction of Solar Cell

The most commonly known solar cell is configured as a large-area p-n junction made from silicon. As a simplification, one can imagine bringing a layer of n-type silicon into direct contact with a layer of p-type silicon. In practice, p-n junctions of silicon solar cells are not made in this way, but rather by diffusing an n-type dopant into one side of a p-type wafer (or vice versa).

If a piece of p-type silicon is placed in intimate contact with a piece of n-type silicon, then a diffusion of electrons occurs from the

If a piece of p-type silicon is placed in intimate contact with a piece of n-type silicon, then a diffusion of electrons occurs from the

Saturday, September 25, 2010

Thin-film solar cells

In 2002, the highest reported efficiency for thin film solar cells based on CdTe is 18%, which was achieved by research at Sheffield Hallam University, although this has not been confirmed by an external test laboratory.

The US national renewable energy research facility NREL achieved an efficiency of 19.9% for the solar cells based on copper indium gallium selenide thin films, also known as CIGS .

NREL has since developed a robot that builds and analyzes the efficiency of thin-film solar cells with the goal of increasing the efficiency by testing the cells in different situations.

These CIGS films have been grown by

The US national renewable energy research facility NREL achieved an efficiency of 19.9% for the solar cells based on copper indium gallium selenide thin films, also known as CIGS .

NREL has since developed a robot that builds and analyzes the efficiency of thin-film solar cells with the goal of increasing the efficiency by testing the cells in different situations.

These CIGS films have been grown by

Friday, September 24, 2010

Crystalline silicon

Basic structure of a silicon based solar cell and its working mechanism.

By far, the most prevalent bulk material for solar cells is crystalline silicon (abbreviated as a group as c-Si), also known as "solar grade silicon". Bulk silicon is separated into multiple categories according to crystallinity and crystal size in the resulting ingot, ribbon, or wafer.

- monocrystalline silicon (c-Si): often made using the Czochralski process. Single-crystal wafer cells tend to be expensive, and because they are cut from cylindrical ingots, do not

Thursday, September 23, 2010

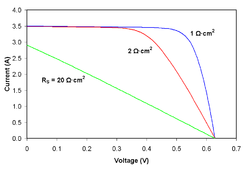

Series resistance

Effect of series resistance on the current-voltage characteristics of a solar cell

As series resistance increases, the voltage drop between the junction voltage and the terminal voltage becomes greater for the same flow of current. The result is that the current-controlled portion of the I-V curve begins to sag toward the origin, producing a significant decrease in the terminal voltage V and a slight reduction in ISC, the short-circuit current. Very high values of RS will also

Wednesday, September 22, 2010

Cell Temperature | Solar Cell

Effect of temperature on the current-voltage characteristics of a solar cell

Temperature affects the characteristic equation in two ways: directly, via T in the exponential term, and indirectly via its effect on I0 (strictly speaking, temperature affects all of the terms, but these two far more significantly than the others). While increasing T reduces the magnitude of the exponent in the characteristic equation, the value of I0 increases exponentially with T. The net effect is to

Tuesday, September 21, 2010

High-efficiency cells

High-efficiency solar cells are a class of solar cell that can generate more electricity per incident solar power unit (watt/watt). Much of the industry is focused on the most cost efficient technologies in terms of cost per generated power.

The two main strategies to bring down the cost of photovoltaic electricity are increasing the efficiency of the cells and decreasing their cost per unit area. However, increasing the efficiency of a solar cell without

The two main strategies to bring down the cost of photovoltaic electricity are increasing the efficiency of the cells and decreasing their cost per unit area. However, increasing the efficiency of a solar cell without

Wednesday, September 15, 2010

Silicon solar cell device manufacture

Solar-powered scientific calculator

Because solar cells are semiconductor devices, they share many of the same processing and manufacturing techniques as other semiconductor devices such as computer and memory chips. However, the stringent requirements for cleanliness and quality control of semiconductor fabrication are a little more relaxed for solar cells. Most large-scale commercial solar cell factories today make screen printed poly-crystalline silicon solar cells. Single crystalline wafers which are used in the semiconductor industry can be made into excellent high efficiency solar cells, but

Tuesday, September 14, 2010

Transparent conductors

Many new solar cells use transparent thin films that are also conductors of electrical charge. The dominant conductive thin films used in research now are transparent conductive oxides (abbreviated "TCO"), and include fluorine-doped tin oxide (SnO2:F, or "FTO"), doped zinc oxide (e.g.: ZnO:Al), and indium tin oxide (abbreviated "ITO").

These conductive films are also used in the

These conductive films are also used in the

Friday, September 10, 2010

Silicon thin films

Silicon thin-film cells are mainly deposited by chemical vapor deposition (typically plasma-enhanced (PE-CVD)) from silane gas and hydrogen gas. Depending on the deposition parameters, this can yield:

- Amorphous silicon (a-Si or a-Si:H)

- Protocrystalline silicon or

- Nanocrystalline silicon (nc-Si or nc-Si:H), also called microcrystalline silicon.

Sunday, September 5, 2010

Organic polymer solar cells

Organic solar cells and polymer solar cells are built from thin films (typically 100 nm) of organic semiconductors such as polymers and small-molecule compounds like polyphenylene vinylene, copper phthalocyanine (a blue or green organic pigment) and carbon fullerenes and fullerene derivatives such as

Friday, September 3, 2010

Solar Cells History

The term "photovoltaic" comes from the Greek φῶς (phōs) meaning "light", and "voltaic", meaning electric, from the name of the Italian physicist Volta, after whom a unit of electro-motive force, the volt, is named. The term "photo-voltaic" has been in use in English since 1849.

The photovoltaic effect was first recognized in 1839 by French physicist A. E. Becquerel. However, it was not until 1883 that the first solar cell was built, by

The photovoltaic effect was first recognized in 1839 by French physicist A. E. Becquerel. However, it was not until 1883 that the first solar cell was built, by

Subscribe to:

Posts (Atom)